LINNIG

Engine Cooling Systems

Demand-meeting engine cooling at high efficiency

Trust the Original – LINNIG Engine Cooling Systems

Efficient engine cooling means saving fuel

The primary units of LINNIG’s engine cooling systems are electronically controlled electromagnetic fan clutches, available in 2- and 3-speed versions. These clutch systems enable demand-meeting engine cooling to be realized by reducing to the required fan speed. That directly leads to cutting fuel costs at optimum efficiency.

Accurate heat removal depending on individual output curve

Depending on the application, the design of the fan clutch adapts to the customer‘s output curve and can thus ensure accurate, very swift heat removal: Within 0.5 seconds the fan is fully engaged, and thus draws off heat immediately. The maximum engine power is always available.

Precision. Cooling. Efficiency.

Innovative transmission technology for a flexible, efficient cooling system – compact, lightweight, and ISO 9001 & 14001 certified. Made in Markdorf, Germany.

*compared to other systems

Note: Our drive has an efficiency of 98%

100%

Core

business

50%

Weight reduction

30%

Lower

costs*

35%

Higher efficiency*

Working principle

Various installation possibilities

Depending on vehicle type and installation situation, various possibilities are given:

- Installation with open radiator-fan bearing frame

- Installation at the water pump

- Engine-mounted installation

- Installation with angle gearbox

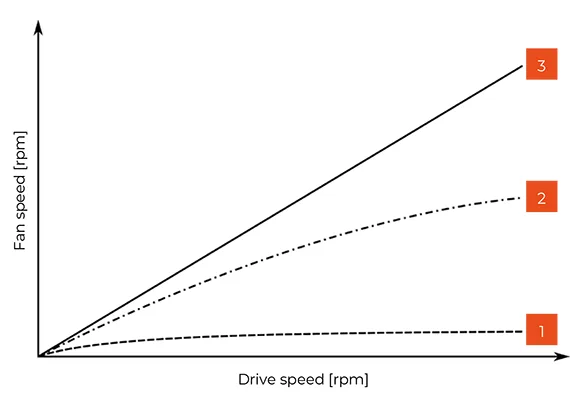

2-speed fan clutch with two speed ranges

Reduced speed (2): When the electromagnetic clutch is deactivated (disengaged), the fan blade can reach speeds of up to 1,200 RPM by means of a contact- and wear-free operating eddy current system.

1:1 ratio (3): When the electromagnetic clutch is activated via a temperature sensor, the fan blade runs synchronous with the drive pulley.

3-speed fan clutch with three speed ranges

In the 3-speed version, the eddy current system can be activated and deactivated. This enables very low fan speed and thus swift warming-up of the engine.

Very low speed (1): When both electromagnetic clutches are deactivated, the fan blade runs at a speed below 100 RPM, owing to the interior friction conditions.

Medium speed (2): When the inner electromagnetic clutch is activated via the fi rst temperature sensor, the fan blade can reach speeds of up to 1,200 RPM by means of a contact- and wear-free operating eddy current system.

1:1 ratio (3): When the outer electromagnetic clutch is activated via the second temperature sensor, the fan blade runs synchronous with the drive pulley.

Electromagnetic fan clutches

Benefits at a glance

- Compact design & High efficiency

- No “morning sickness”

- Precise fan control

- Demand-oriented cooling reduces fuel consumption and CO2 output

- The RPM characteristic of the eddy-current stage can be specified according to customer requirements

- Low noise level in comparison to rigid drives: The specified noise limit values are clearly fallen below

- Simple installation and removal

- Maintenance-free drive means low downtime

- Long service life

Additional advantages of the 3-speed version

- Especially in countries with low temperatures, the 3-speed solution prevents overcooling of the engine.

- Rapid engine warm-up

>> All fan clutches are also available with erase diode

Technical specifications

Fan clutches for installation with open radiator-fan bearing frame (2-speed / 3-speed)

Fan clutches for installation at the water pump (2-speed / 3-speed)

Fan clutches for engine-mounted installation (2-speed / 3-speed)

Angle gearboxes and electromagnetic fan clutches

Benefits at a glance

- Easy to service

- Long service life through integrated gearbox ventilation

- Optimized ball bearings

- Long oil-change intervals

- Noise reduction

- Efficiency 98%